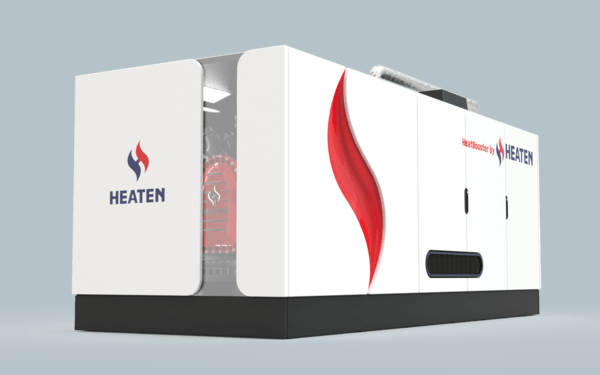

THE NEXT GENERATION OF INDUSTRIAL HEAT PUMP IS HERE

Biggest piston-based high-temperature industrial heat pump

Decarbonize your processes with our highly efficient and flexible technology!

INDUSTRIAL HEAT PUMPS BUILT ON PROVEN PISTON TECHNOLOGY

Reliable technology to replace fossil fuels

Our compact, high-temperature heat pumps are powered by proven piston compressor technology—delivering reliable output up to 200°C. Designed for industrial use, they offer scalable performance from pilot to full-scale integration. Flexible supply temperatures reduce the need for multiple systems and give engineers more freedom in process design.

Our heat pumps are a sound long-term investment. Even if regulations change or specific refrigerants are phased out, the system remains compatible—keeping you future-ready and compliant with evolving standards.

OUR EFFECIENT PISTON COMPRESSOR TECHNOLOGY

The benefits at glance

Temperature flexibility

Unlike other compressors, our piston compressor adapts to varying operating conditions, including source temperatures from 10-150°C and sink temperatures up to 200°C.

Rapid start-up

A warm start in under 15 minutes means you can react fast and flexibly to dynamic energy prices and supply fluctuations—ideal for modern energy systems.

High partial load output

Our technology is efficient across the board—even at partial load from 20 to 100% thermal output in the MWth range. That keeps energy losses to a minimum and cuts operating costs.

Fast load changes

Switch from full load to partial load in just 30 seconds. That gives you amazing operational flexibility and rapid reaction times to changing process demands.

Unique pressure range

Thanks to an extraordinary pressure design (up to 45 bar condensation and 18 bar evaporation), our heat pump performs efficiently under extreme conditions. Ideal for demanding industrial applications.

Refrigerant flexibility

One hardware platform compatible with both HFO and HC refrigerants—future-ready and regulation-compliant.

WHAT TO KNOW ABOUT THE TECHNOLOGY BEHIND OUR INDUSTRIAL HEAT PUMP?

We have the answers

-

What thermodynamic principle does the HeatBooster use?

The HeatBooster is based on the principle of mechanical vapour compression. It uses a two-stage compression process (piston compressor) to manage big temperature rises efficiently. Heat is increased up to 200°C in two stages. This multi-stage compression is crucial for high COP values when temperature differentials are large—and a key feature of our two-stage heat pump technology.

-

What is the HeatBooster’s COP value and how is it impacted by temperature rises?

The Coefficient of Performance (COP) of the HeatBooster typically ranges from 2 to 5, depending on operating conditions. It achieves a high COP of over 50% of the Carnot Limit—even when there are large temperature rises. This is a clear sign of the excellent Carnot efficiency heat pump performance. Thanks to the two-stage compression principle, the COP stays high even when there are big differences between the heat source and the heat sink.

-

What benefits does the piston compressor offer for industrial applications?

The piston compressor is the heart of the HeatBooster. As the largest piston-based compressor on the market, it offers impressive efficiency, durability, and flexibility. Its benefits include:

- High Performance: It can deliver an output temperature of 200°C and a high COP, even with considerable temperature rises.

- Flexibility: It offers rapid start-up (under 15 minutes), fast load changes (full to partial load in 30 seconds), and the ability to operate efficiently at partial loads as low as 20%.

- Durability: The technology is proven to operate for 30,000 hours without maintenance and is designed for a service life of over 20 years.

-

Which refrigerants can be used in the HeatBooster?

The HeatBooster is compatible with a wide range of fluids, including HFOs and HCs. Our piston compressors are designed with a variable compression ratio, allowing you to use a variety of refrigerants with the same hardware. This means you can start with one refrigerant and switch later without major modifications. This provides flexibility for batch processes, supports compliance with evolving regulations, and helps future-proof your investment against potential refrigerant bans.

-

When should I use a closed-loop steam/steam heat pump?

A closed-loop steam/steam heat pump is ideal when the heat source and sink must remain separated. This is crucial for contamination-sensitive processes (e.g., pharmaceuticals, semiconductors) or when the process involves polluted or clean steam. Since the working fluid does not contact the process medium, this configuration is well-suited for vacuum or low-pressure steam applications. It also allows for greater temperature lifts per stage (above 60 K) and offers more installation flexibility by allowing the compressor and heat exchangers to be placed separately.

Still have questions?

Our experts are ready to help you find the perfect solution for your specific needs.

THERMODYNAMIC CYCLE HEAT PUMP

A brief guide to how it all works

Our very high temperature heat pump is built around a thermodynamic process (the Carnot cycle), during which a refrigerant is constantly switching between its liquid and gaseous states.

At low temperatures, the refrigerant draws heat from its surroundings. Next, it is compressed and gives up its heat at a higher temperature, passing it on to the heating system via a regenerative heat exchanger.

EXPLORE WHATS BEHIND THE PRODUCT

Discover how Heaten is

transforming industrial heating

Piston compressor heat pump

Unused waste heat is easy to find. Recovering that energy with our industrial heat pump can transform it into valuable process heat.

Headline

Add your content here.