The heat pump for more output and a better future

Say goodbye to conventional fossil fuel boilers! Our HeatBooster is a next-generation high-temperature heat pump designed for heavy-duty industrial processes. What sets it apart? It's all about smarter energy and powerful performance:

Harnesses waste heat: Our powerful heat pump takes energy from waste water or steam (from 10 to 150 °C) and gives it a serious boost.

Upgrades to usable process heat: It delivers hot water from 90 to 200 °C and heat pump steam up to 200 °C and 10 bar(a).

Built on proven tech: It's powered by our proprietary piston compressor technology, ensuring maximum dependability and high efficiency—even at partial load down to 20% capacity.

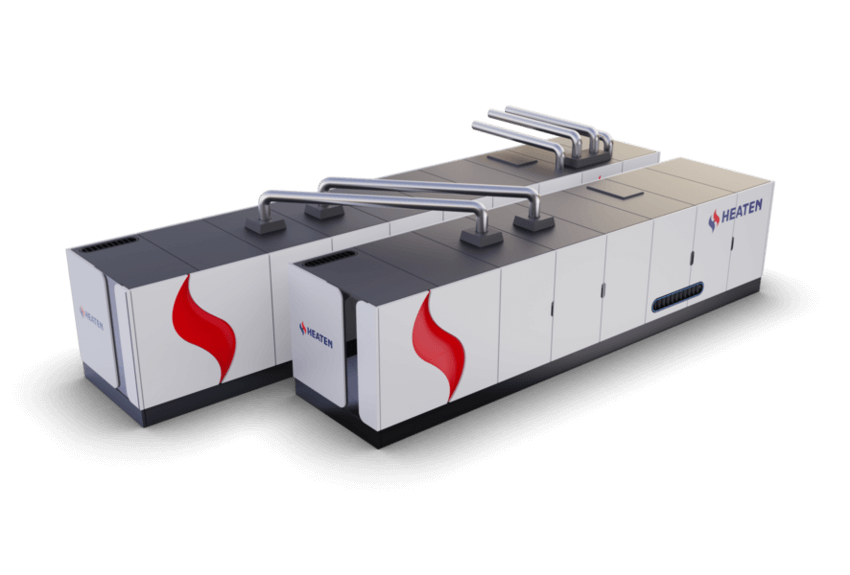

Completely scalable: Start with a single unit (1–10 MWth) and scale up to 50+ MWth by combining multiple modules. This means you can invest in phases and get full system redundancy.

Why it matters: Our HeatBooster reuses energy you already have and cuts emissions.

REDEFINING WASTE HEAT

The HeatBooster HBL4 & HBL16

Our HeatBooster high-temperature heat pumps are advanced technology—and paving the way for a carbon-neutral future in industry. Not only is it a reliable supply system for heat, it’s also driving down energy costs and power consumption, minimizes CO2 emissions and saving water significantly. Check out the details you get per heat pump:

CO2

Up to 12,000 CO2 reduction annually

85%

Up to 85% energy savings

40,000 m3

Up to 40,000 m³ potential water savings per year

OUR INDUSTRIAL HEAT PUMPS SYSTEM

The benefits at a glance

Integrating our industrial heat pump system reduce energy costs, minimize CO2 emissions, and save water—all in one system.

One of the most flexible solutions on the market, delivering high performance today and future-ready scalability and refrigerant compatibility for tomorrow.

Thermal Output

Delivers 1–10 MWth per heat pump, scalable to 50+ MWth for large industrial systems.

High Efficiency

Consistent COP and excellent part-load performance—even at 20% thermal output.

Modular Integration

Parallel, cascade, or 2-stage configurations to match your process needs.

Refrigerant Flexibility

One hardware platform compatible with both HFO and HC refrigerants—future-ready and regulation-compliant.

Exceptional Efficiency & Reliability

COP > 50% of Carnot with flat efficiency curve

Exceptional Efficiency & Reliability

COP > 50% of Carnot with flat efficiency curve

Modular Scalability & Design

1–8 MW modules, expandable to 50 MW

Fuel Flexibility & Ultra-Low GWP Fluids

Works with HFOs/HCs & ultra‑low‑GWP fluids

How do high-temperature heat pumps work?

Dive into the details—download our full technical data sheets and specs!

| Length | mm | 9,000 |

| Width | mm | 2,400 |

| Hight | mm | 2,500 |

| Temperature heat source | 10-150°C |

| Temperature heat sink | 90-200°C (HC), 90-165°C (HFO) |

| Thermal power range | 0.8-2.5 MWth |

| Length | mm | 9,500 |

| Width | mm | 2,700 |

| Hight | mm | 2,700 |

| Temperature heat source | 10-150 °C |

| Outlet pressure heat sink | 10 bar(a) (HC), 6 bar(a) (HFO) |

| Thermal power | 0.8-2.5 MWth |

| Length | mm | 10,000 |

| Width | mm | 2,700 |

| Hight | mm | 2,900 |

| Temperature heat source | 0.15 bar(a) - 4.7 bar(a) |

| Outlet pressure heat sink | 10 bar(a) (HC), 6 bar(a) (HFO) |

| Thermal power | 0.8-2.5 MWth |

| Length | mm | 9,000 & 12,000 (2 skids) |

| Width | mm | 2,400 |

| Hight | mm | 2,500 |

| Temperature heat source | 10-150 °C |

| Temperature heat sink | 90-200 °C |

| Thermal power | 3.2-10 MWth |

| Length | mm | 9,000 & 12,000 (2 skids) |

| Width | mm | 2,400 |

| Hight | mm | 2,500 |

| Temperature heat source | 10-150 °C |

| Outlet pressure heat sink | 10 bar(a) (HC), 6 bar(a) (HFO) |

| Thermal power | 3.2-10 MWth |

| Length | mm | 9,000 & 12,000 (2 skids) |

| Width | mm | 2,400 |

| Hight | mm | 2,500 |

| Temperature heat source | 0.15 bar(a) - 4.7 bar(a) |

| Outlet pressure heat sink | 10 bar(a) (HC), 6 bar(a) (HFO) |

| Thermal power | 3.2-10 MWth |

This solution is ideal for scalable projects and supports phased investment and flexible growth. Companies can start off small and gradually grow their capacities. That gives them a futureproof investment strategy that combines maximum efficiency with technical scalability.

André Bechem

VP Sales & Product Management

Very high temperature heat pumps—a detailed insight

Technology

Dive into the tech that powers the energy transition.

Headline

Add your content here.

Your partner for the entire life cycle

We are committed to supporting you throughout the entire lifecycle of your system, delivering the services you need to achieve peak performance from your assets. Wherever you are, whatever you need, nd whenever you need us—we are with you at every step of your equipment’s journey.

Backed by our experienced service technicians and more than 1,000 colleagues from our strategic partner INNIO, we offer global reach, rapid response, and deep technical expertise. Together, we provide the knowledge and support to reduce operating costs, maximize uptime, and ensure reliable, future-proof performance for your system.

Maintenance & Lifecycle Services

- Planned maintenance (predictive) and unplanned repairs (corrective)

- Scheduled maintenance programs—includes annual oil service (oil replacement and leak checks), minor overhaul at 40,000 hours, and major overhaul at 80,000 hours

- 20+ year system lifetime with proper maintenance

- Predictable operational costs across the asset’s lifecycle

- Optional upgrades to extend system performance and flexibility

- HEATEN offers different types of contractual service agreements

Monitoring & Support

- Remote monitoring and diagnostics

- Integrated system control via “My Plant” interface

- 24/7/365 hotline—fast response through global contact centres

- Guaranteed reaction times and support availability

- Downtime optimization—planned in consultation with your operations

Parts & Field Services

- Certified field technician dispatch

- Outage planning and on-site support

- OEM spare parts—always up to date

- Piston-based platform—compatible with standard tools and technician skills

Scalability & Project Delivery

HEATEN and INNIO Group—with over 4,500 experts and a service network spanning more than 100 countries—have established a strategic partnership that combines advanced engine and heat pump technologies to deliver CO2-free heat and support customers on their path to decarbonization.

WANT TO KNOW MORE?

You asked, we answered

-

How does a heat pump work?

A heat pump transfers thermal energy from a lower temperature source (like industrial waste heat) to a higher temperature sink (like process steam or hot water), using mechanical compression. HEATEN’s HeatBooster uses a piston-based compressor to efficiently generate high-temperature steam up to 180 °C or water—up to 200 °C—making it ideal for industrial decarbonization.

-

What’s the COP, and how does temperature lift affect it?

The Coefficient of Performance (COP) measures how efficiently a heat pump converts electricity into useful heat. Higher COP = more heat per unit of electricity.

A lower temperature lift (smaller gap between source and sink temperatures) generally results in a higher COP. HEATEN’s piston-based technology performs exceptionally well even at large temperature lifts, maintaining relatively high COPs where other technologies often drop off.

-

How many references do you have? Where can I see the heat pump?

You can see the HeatBooster HBL4 in operation at our Remscheid testbed in Germany.

Full commercial reference sites are expected to be online soon.

-

What is the maximum steam or water temperature on the heat sink side?

The HeatBooster delivers:

- Steam up to 180 °C.

- Water up to 200 °C.

This allows it to replace fossil-fuel-based systems in a wide variety of high-temperature industrial applications.

-

What is the maximum and minimum power output?

Current configurations cover a broad power range:

- Minimum thermal output: ~1 MWth (starting with the HBL4 model)

- Maximum system output: 50+ MWth, achievable via modular system integration (parallel, cascade, 2-stage setups)

This enables customers to start small and scale as needed, while also allowing for redundancy and efficiency optimization.

Need advice?

Available soon—the HeatBooster HBL16

The HBL16 is the next generation of our industrial high-temperature heat pumps—and it’s coming soon!